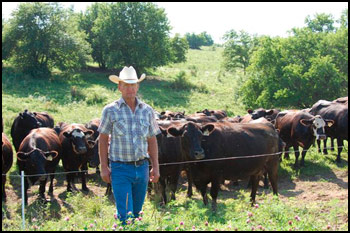

Pete Mitts (left) and John Osborn used their first grid-marketing experience as motivation to change.

Eleven Years Later

CAB partners spent more than a decade building a

commercial Angus dynasty.

In the 1990s, the cattle business was going all right for John Osborn, Savannah, Mo. Better than crop farming, which he had recently turned over to custom operators. Not great, but mostly all right.

He built up a generic black cow herd and backgrounded some sale barn stockers to go with his calves. Some of those would top the market in March, but sometimes he lost money, too.

Their first year selling on the grid (1997) was a "discovery year," John Osborn says. "We found out our cattle weren't any better than anybody else's." That has changed.

.To spread the risk, Osborn decided to expand into finishing cattle, encouraged by neighbor Pete Mitts, who had a black cow herd of his own. Moreover, he had experience in balancing rations from his years in the feed business, and he was ready to join Osborn as a student of genetics and performance in the changing industry.

Instead of buying sale barn cattle, in 1997 Osborn bought calves from Mitts to go with his own. He later sold them on a value-based grid.

"It was our discovery year," Osborn says now. "We found out our cattle weren't any better than anybody else's."

That meant barely 60% graded USDA Choice with a handful accepted for the Certified Angus Beef® (CAB®) brand. It also meant 40% graded as Selects, "which you really don't want to sell on the grid," Mitts advises.

The news was so daunting that the men felt compelled to take corrective action. Mitts may have had a better handle on his herd records, but was glad to find ways to track and eliminate cows producing Select, Yield Grade (YG) 4s. "That's about as poor as one can get. No change in feeding strategy can fix it," he says.

Osborn literally decimated his herd, keeping only 35 heifers from his top cows, and only after springing for better registered Angus bulls. Like Mitts, he turned to Green Garden Angus, Lorraine, Kan. "We built back up from those 35 heifers we calved in 2001," Osborn says, keeping only replacements from his herd or buying from Mitts, who took a longer-term culling approach.

Seeing positive results

After 10 years, overwhelming evidence said the rebuilt herds were on solid genetic ground. Mitts' Broken M Ranch 2007 steer results were featured in the Green Garden sale book. There was a striking correlation between quality grade and age of dam, with steers from the youngest cows making 50% USDA Prime, compared to none from the oldest dams. All 128 head averaged 81.25% CAB.

"As we were gathering all the carcass data on steer mates, we applied it to the heifers," Mitts says. "That's how you build a herd, stacking genetics in the females; you don't do it through the male side." Well, given that you do buy the best balanced-trait, registered Angus bulls you can afford.

The two have used some artificial insemination (AI), but they rely almost entirely on natural service.

"That's my downfall," Mitts says, laughing. "I like to buy bulls." Osborn, on the other hand, uses some AI on heifers to save buying so many bulls. But the two swap bulls occasionally to suit breeding needs.

Regardless, they both insist on multipurpose bulls. "I look at the carcass data, but I want the milk right on them," Mitts says. "I want the birth weight and growth right on them and I want the carcass right on them. You've got to have marbling, in cows that have a calf every year."

Investing in good bulls brings risk, which is why they keep spares. "If you've got bulls, you might as well plan on losing some," Osborn says. "Stuff just happens. You could have 400 head in a pasture, and it will be your bull that will get struck by lightning."

That conservative nature fits the quality mind-set: Do things right the first time and be prepared. "If you're going to raise something, then raise the best quality you can," Mitts says. "Eventually you will see the financial benefits."

The plan is working. Their backgrounding yard became a heifer development center that uses data from the finishing pens, which expanded to 600-head capacity. Heifer volume soon grew to 200, then 300 head as carcass data led the way and a dozen smaller-scale neighbors joined in the loop.

"As we were gathering all the carcass data on steer mates, we applied it to the heifers," Pete Mitts says. "That's how you build a herd, stacking genetics in the females; you don't do it through the male side."

."Most of them have 30 to 50 cows and a job in town, though there are a couple of larger herds," Mitts says. "Developing heifers is kind of hard for them, where they'd have to have a place and different bulls, so we sell them what they need." The same correlation holds, that the younger the cows are in neighbors' herds, the higher the calves grade.

Speaking of young, the duo practices early weaning with a 90-day average age target from first-calf heifers. "I started doing that in the 1990s because I was losing the top 25% of my heifers the first year," Mitts says. "Anything that could wean a 500-pound (lb.) calf as a first-calf heifer was usually open."

Osborn says the calves only need to reach the two-weight category to succeed. "Those 200- to 250-lb. weaned calves hit the bunks and do nothing but take off," he says. "That's because they got a good start."

A partnership that works

The Mitts-Osborn partnership is a natural joint venture with no more structure than a handshake, although Mitts is now the official feedlot consultant. Today, each of them own and manage carefully selected 350-cow Angus herds, selling young cows and heifers to those neighbors, all part of a homegrown alliance.

In 2009, Osborn Farms became a CAB-licensed feedlot drawing only from known sources, with all cattle owned by Mitts or Osborn. The latter had become a U.S. Premium Beef (USPB) member in 2007 and then an AngusSource®-approved process-verified program (PVP) feedyard. He only buys AngusSource-tagged calves with genetics that trace back to their herds.

Proof of what this pool of cattle can do continues unabated, as the feedlot easily won Northeast Region third-quarter honors in the AngusSource Carcass Challenge. The 43 head of mixed steers and heifers tallied 97.7% CAB and CAB Prime at National Beef. Read more.

That team will be hard to beat in the finals, as the sports reporters would say. But throughout the year, data from Osborn Farms finished cattle looks impressive. Noting that their first 236 head harvested since joining the CAB Feedlot-Licensing Program (FLP) this spring went 78% CAB or Prime — four times the national average — Mitts could only hope the fall numbers would pick up, as they have. "We beat that number on 500 head last year," he says.

Sorting and weighing are staples of management. "We weigh each head at the beginning, at re-implant and as they leave for the plant," Mitts says. "We don't get carried away with implanting and we don't overfeed, because we try to avoid those minus columns on the grid."

There's a lot of friendly joshing and jostling for bragging rights between the two. Osborn says, "We've done just about everything together for the past 11 years, but we each blame the other for whatever happens."

When Mitts gets the carcass data every few weeks, whoever had the best results from his herd genetics has to buy lunch. The key is, Mitts sees it first. "If we go to lunch and Pete doesn't say anything, then I know he won. He'll say, 'You didn't ask, so I didn't buy.'"

"Or maybe," Mitts says, "I'll have 20 on a bunch, but he'll have three Primes that beat their average. John will tell me mine were better, or he would have had more ready to sell in that group, so I should buy lunch. There are all kinds of ways to interpret data."

Could be, but any way you look at it, the two have a pipeline full of straightbred Angus cattle that seem to deliver more than a free lunch. With the continuous injection of data-guided females that carry genetics stacked toward perfection, tomorrow looks even better.

Click here to return to front page.

Click here to see more marketing-related stories on the Marketing page.

[Click here to go to the top of the page.]